NSF Funded Companies: In Partnership with CEP

These articles were written in partnership with the Chemical Engineering Progress about the work of some of our NSF funded companies.

Legume Based Innovation Promises New Stealth Health Snacks

Processed foods are a staple in the American diet, comprising more than half of adult energy intake. When eaten in excess, these shelf-stable, convenient, and tasty foods are known contributors to obesity, heart disease, cancer, Type 2 diabetes, and gastrointestinal disorders. However, changing habits and taste preferences to encourage healthier eating is a challenge. Processed foods are known for their excellent sensory properties and high palatability but are often calorically dense and contain elevated levels of starches, sugars, saturated fat, and salt, and low amounts of beneficial macro and micronutrients. Food is a complex matrix of fats, fibers, starches, sugars, proteins, vitamins, minerals, and water, all of which contribute to sensory qualities such as texture, mouthfeel, and flavor perception that are critical in the experience of food consumption.

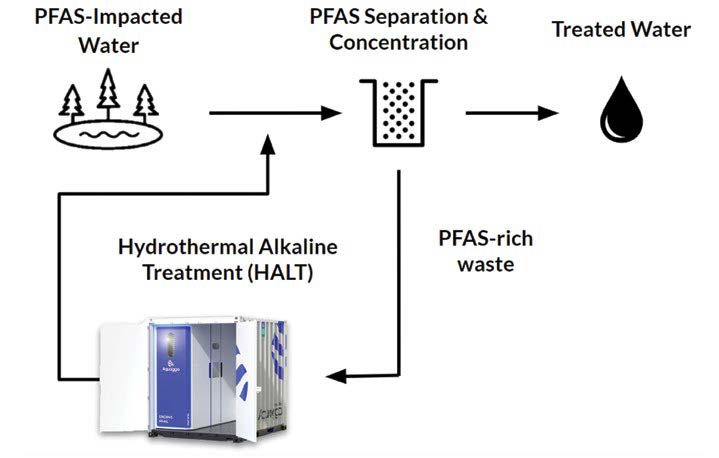

Learn MoreProviding Complete Hydrothermal Destruction of PFAS

Per- and polyfluoroalkyl substances (PFAS) are ubiquitous environmental contaminants found in everything from consumer goods to fire retardants to cosmetics. Their most significant use is in military-grade firefighting foams that have been used for decades, causing widespread contamination of groundwater, drinking water wells, surface water, and soil. Firefighting drills performed at military bases and airports have led to high concentrations of PFAS near military bases, airports, and industrial manufacturing facilities (where PFAS are either used or produced), as well as in landfill leachate.

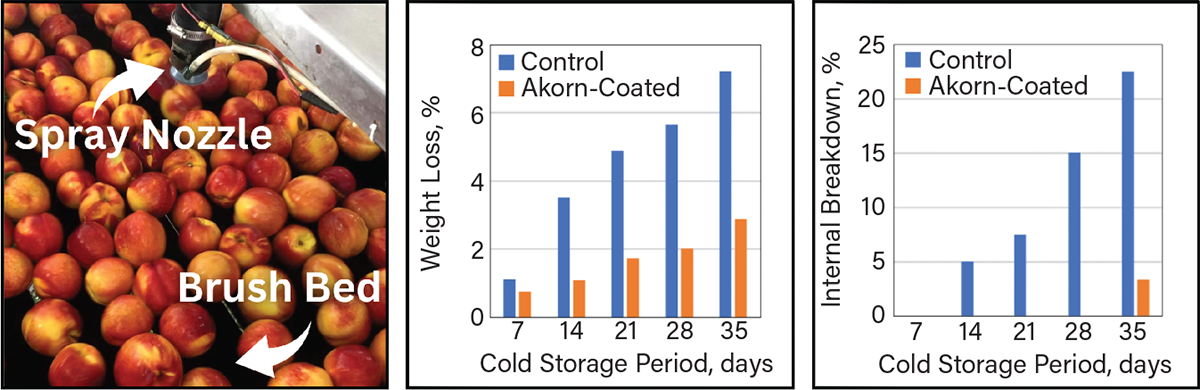

Learn MoreCorn Zein-Based Edible Coatings Reduce Fresh Produce Waste

Nearly 1.3 billion tons of food — almost one-third of the world’s food supply — goes to waste each year. Producing and disposing of this much wasted food consumes 17.6 billion m3 of water and generates 193 million m.t. of greenhouse gases, according to the United Nations (UN) Food and Agriculture Organization (FAO) and the UN Environment Program. Novel food preservation technology could help feed every undernourished person on the planet and reduce the environmental impact of such waste.

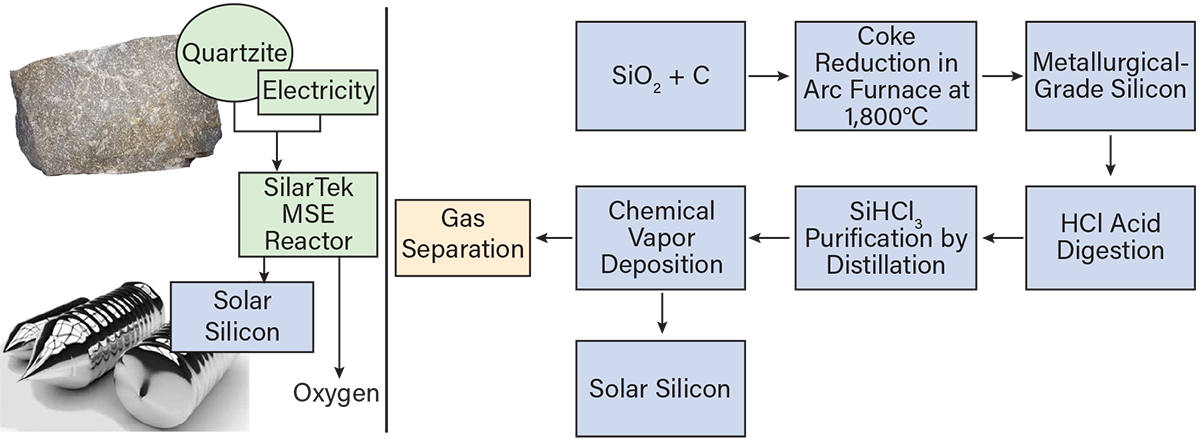

Learn MoreLow-Cost One-Step Production of Solar Silicon from Natural Quartzite

Silicon is the dominant material for photovoltaic (PV) technologies due to its abundance, low cost, and good PV efficiency. Today, the most common way to produce polysilicon for PV applications is via the Siemens process, which consists of carbothermic reduction, synthesis, purification, and chemical vapor deposition of toxic explosive chlorosilanes. This process is inherently complex, difficult to scale, energy-intensive (~300 kWh/kg), and unsafe due to the presence of toxic, flammable, and dangerous chemicals such as silane (SiH4) and hydrochloric acid (HCl). In addition, because it emits a considerable amount of greenhouse gases (GHGs), the Siemens process is a “non-green” production method used for a “green” purpose.

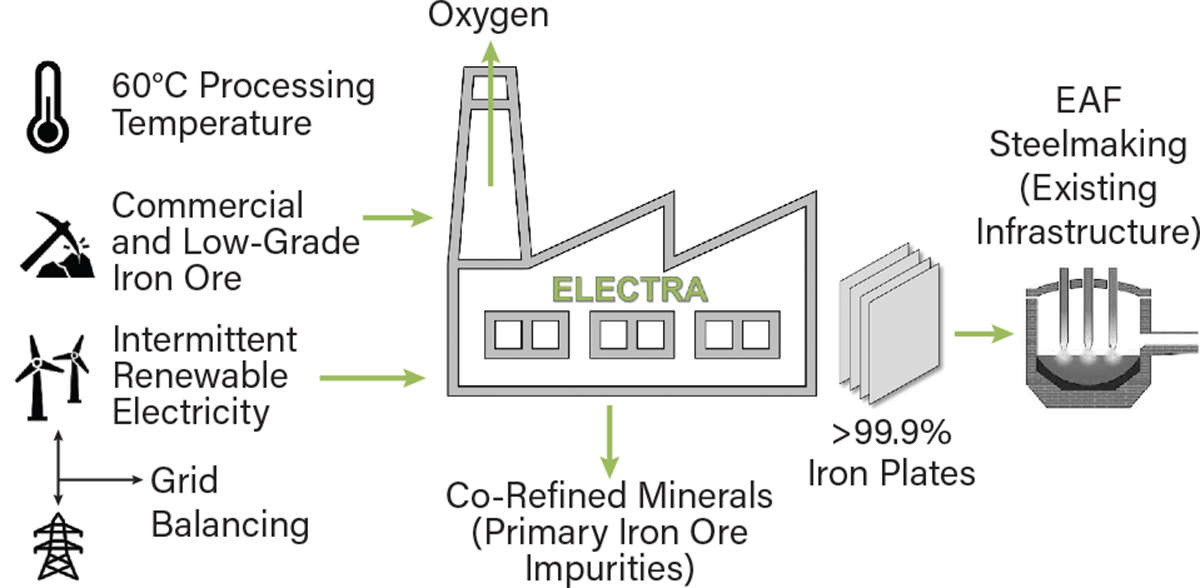

Learn MoreProducing Green Iron with a Zero-Carbon Electrochemical Process

Steel is the backbone of the modern world. The iron-based alloy is essential to construction, transportation, and many other activities tied to higher living standards. However, the iron and steel sector is a major source of carbon dioxide emissions, which are destabilizing the Earth’s climate.

Learn More